Overview

World leader in marine glazing

Since 1995, Somec has been a trailblazer in the naval industry, earning a reputation as the global leader in designing, producing and installing glazed structures for cruise liners. Our unwavering commitment to excellence ensures that we deliver the highest standards of quality, certified durability and cutting-edge technological innovation. Refitting and maintenance services complete our suite of integrated solutions, perfectly tailored to meet the dynamic demands of this ever-evolving sector.

years of experience

in marine glazing

People

specialized in the field

Projects

worldwide since 2013

Design and production

all-in-house to create

bespoke solutions

Somec manages every phase of the project completely in-house.

With this approach, we maintain full control over every detail, ensuring unparalleled quality, excellence and a competitive advantage while meeting production and delivery deadlines. Moreover, it enables us to swiftly address unanticipated incidents, which are the norm in this complex sector.

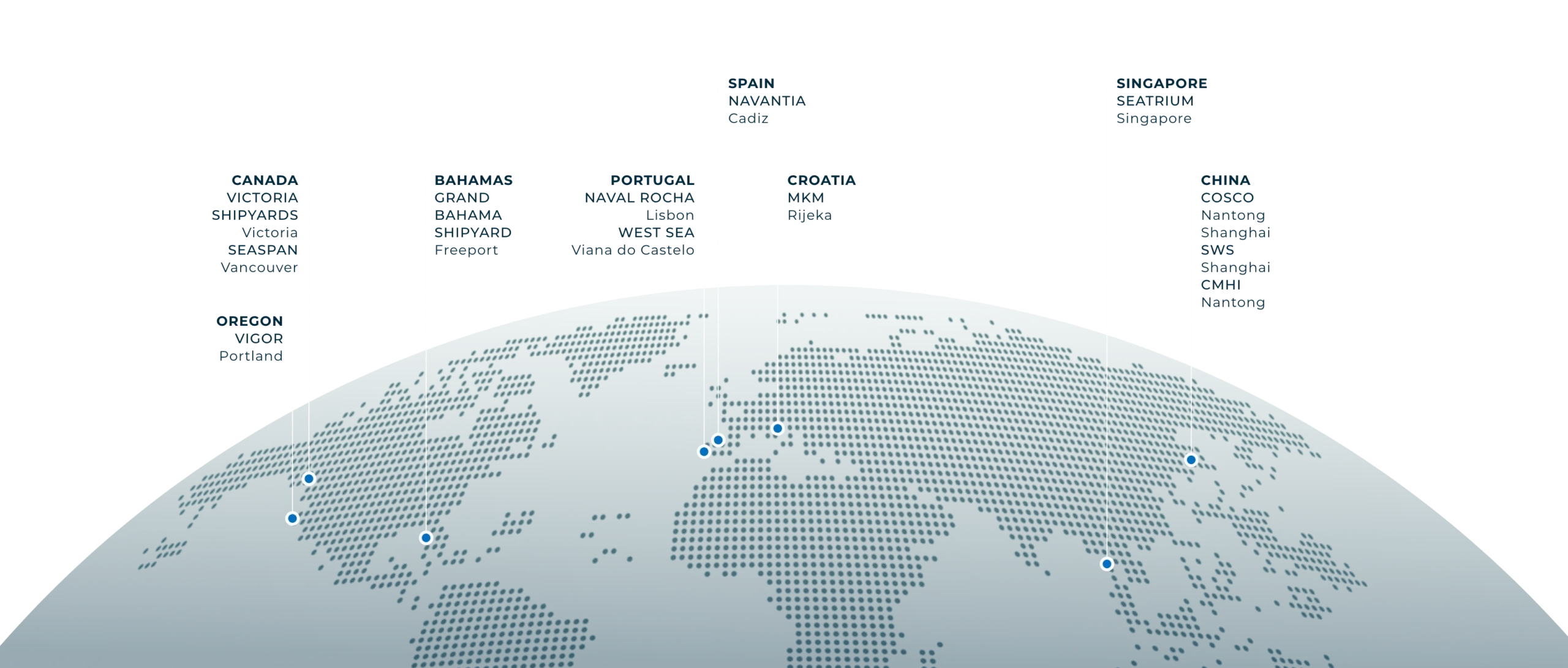

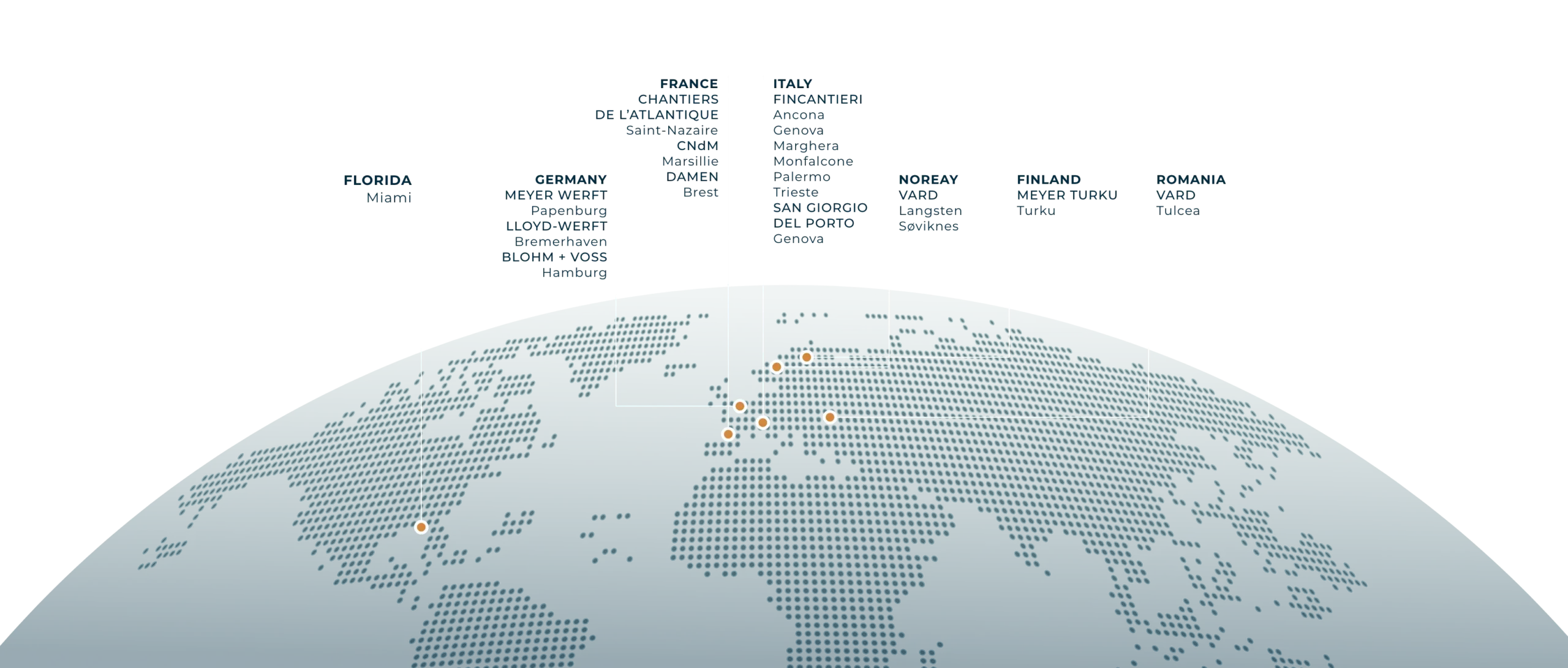

SHIPYARDS AND BRANCHES

WORLDWIDE

We partner with key industry players, including cruise lines and shipbuilders, to develop tailored solutions and projects that meet the sector’s most sophisticated demands.

- SHIPYARDS

- BRANCHES

those who put their trust in us

Shipyards

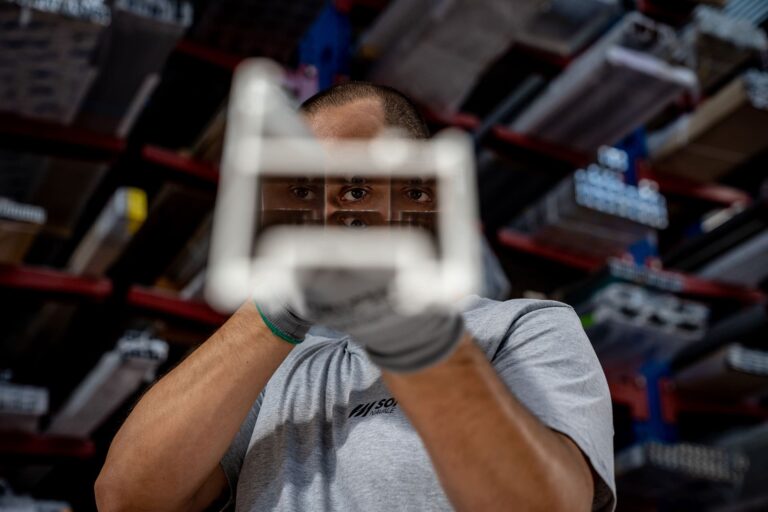

PUTTING PEOPLE FIRST

At Somec, we prioritise investing in our people, fostering a work environment that encourages employees to stay with us long-term. Our rewarding policy, applicable to everyone, is based on clear and measurable KPIs to enhance individual skills.

Every team member has personalised goals, which are defined and monitored every six months to ensure ongoing professional development and shared growth.

GREENER EVERY DAY

We take a responsible approach to waste management by accurately sorting and reusing materials like steel, plastic, cardboard and wood. Our efforts include recycling aluminium in its primary, secondary and tertiary forms, and salvaging 100% of our glass.

We also work closely with our suppliers to reduce plastic use, such as implementing a deposit return system for incoming semi-finished products. All of these actions contribute to reducing our environmental impact and promoting a circular economy.