Production

WE TURN IDEAS INTO CUSTOM, HIGH-PERFORMANCE PRODUCTS

With over 30,000 sqm of space dedicated to design, production, assembly and warehousing, we ensure efficient management of materials and a production process that is always prepared to respond quickly and effectively to our clients’ needs.

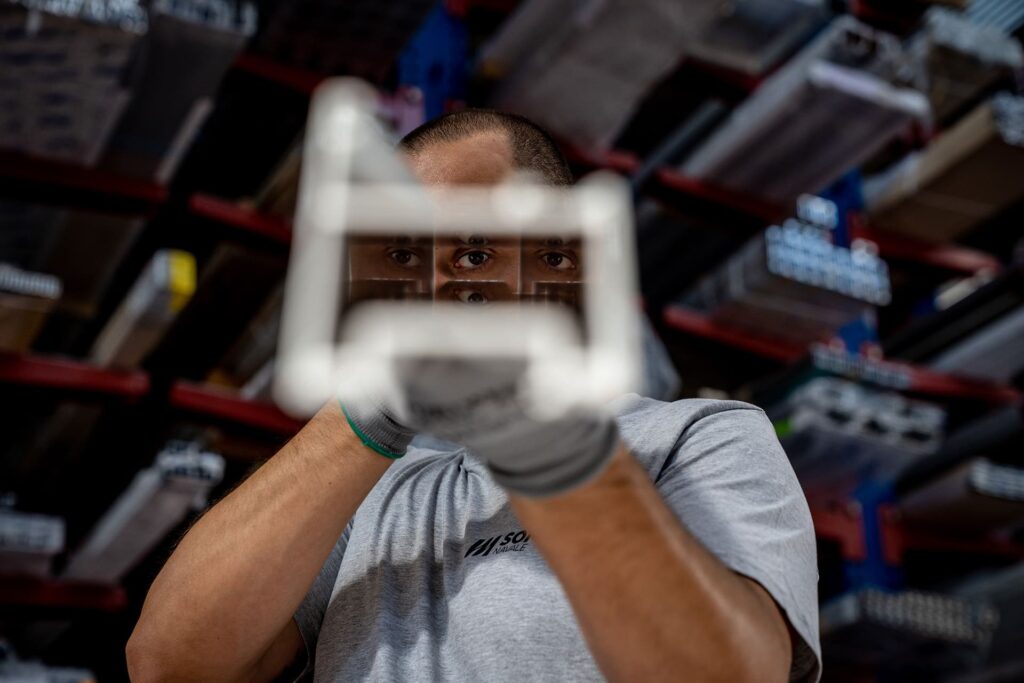

TEAM OF HIGHLY QUALIFIED PROFESSIONALS

Our production team is organised into specialised areas to ensure efficiency and quality at every step of the process. Over 40 operators work on 7 assembly lines, each dedicated to a different product. We also have teams for metal fabrication, profile cutting and machining, and glass manufacturing, with a total of over 70 people working to bring every project to life.

ADVANCED PLANNNING

Our planning is divided into two phases: a global masterplan, that outlines every milestone from design to installation, and a detailed plan that organises every activity down to the smallest detail. With our new Manufacturing Execution System (MES), we monitor and track each production phase in real time, improving quality and control. This system helps us synchronise processes, optimise time; and generate on-the-spot quality reports.

PRODUCTION AND ASSEMBLY

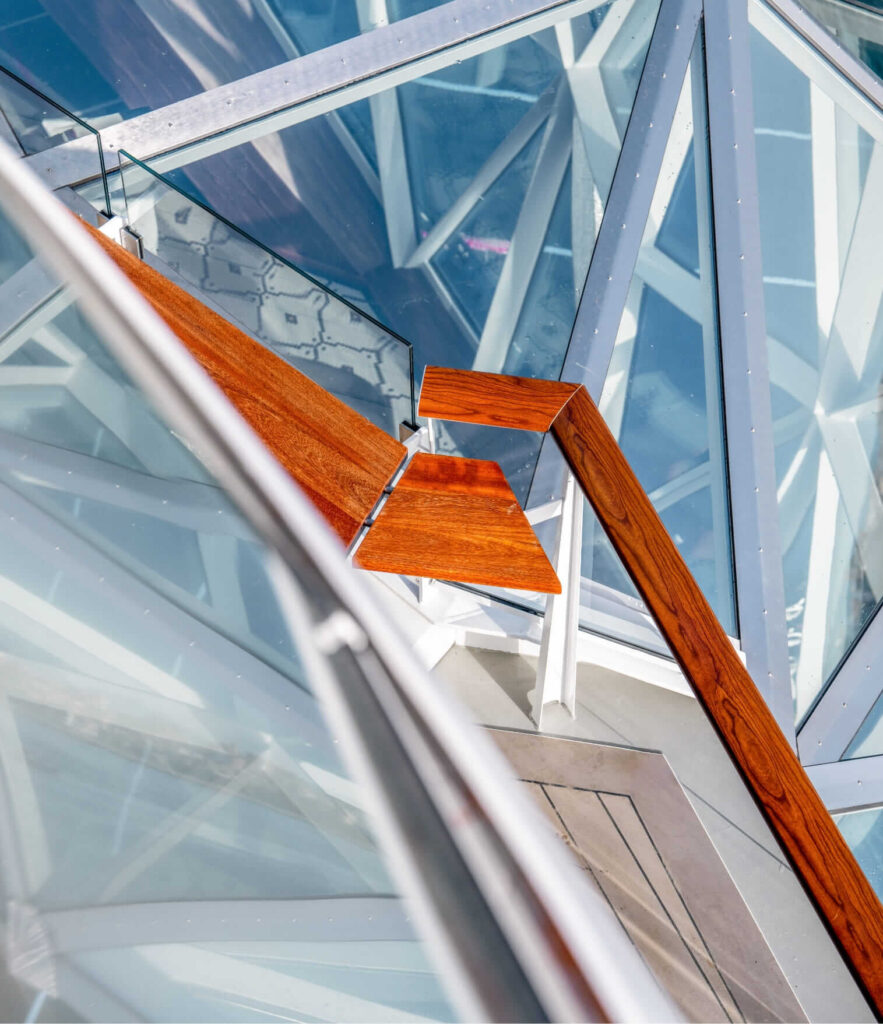

Our production consists of 7 assembly lines, each dedicated to a specific product category:

• subframes and leaves for manual and automated doors and windows

•AVSW systems, which are advanced windows combining fixed and mobile frames, glazed parts and management electronics

• special products like balustrades, partitions, gates and handrails, which require high customisation and are produced in smaller quantities

• pre-fabricated balcony modules and floors

• cabin partitions, both fixed and openable

SPECIALISED CRAFTSMANSHIP

Many projects require specialised craftsmanship, which we provide through our highly skilled workers. For example, our team of certified welders combines advanced technical skills, ongoing professional training and years of experience.

This blend of technology and craftsmanship allows us to tackle the challenges and problems of complex projects, delivering lasting and reliable results.

SURFACE TREATMENTS

At Somec, we understand that surface treatments are crucial for extending the longevity and reliability of our products. That’s why we collaborate with a carefully curated selection of partners who guarantee certified-quality work.

Anodising, whether standard or hard-coat, provides exceptional protection against corrosion and wear, ensuring the metal’s stability and strength over time. Our comprehensive range of treatments is completed with powder coating and aluminium sublimation, enhancing the aesthetic appeal and durability of products.

SHIPPING: ATTENTION TO DETAIL ENSURED

We manage shipping with meticulous care at every stage of the process. Our crates, crafted from recyclable wood or metal, are rigorously tested and certified to guarantee the safety and integrity of our products during transport.

This unwavering attention ensures that we provide reliable, sustainable and secure shipping solutions, protecting our products all the way to their final destination.