Quality

GUARANTEED QUALITY AND EXCELLENCE, FROM RAW MATERIALS TO THE FINAL PRODUCT AND BEYOND

We regularly conduct systematic thorough assessments, tests and monitoring to ensure our products, services and processes meet regulatory requirements and our own high standards of excellence. We believe that only the best quality can bring unique projects to life, and this commitment to quality makes all the difference.

ALUMINIUM WORKSHOP

We handle over 2,000 metric tons of aluminium profiles and machine over 350,000 workpieces in-house, supported by an automated warehouse. With over 500 active dies, we can develop custom profiles that meet architects’ design, functionality and performance requirements.

The profiles are cut with cutting machines for speed, while CNC machinery performs precision operations like drilling, milling and slotting. Our equipment includes high-quality cutting-edge industrial machines, designed to minimise maintenance, even in high-productivity scenarios.

GLASSWARE WORKSHOP

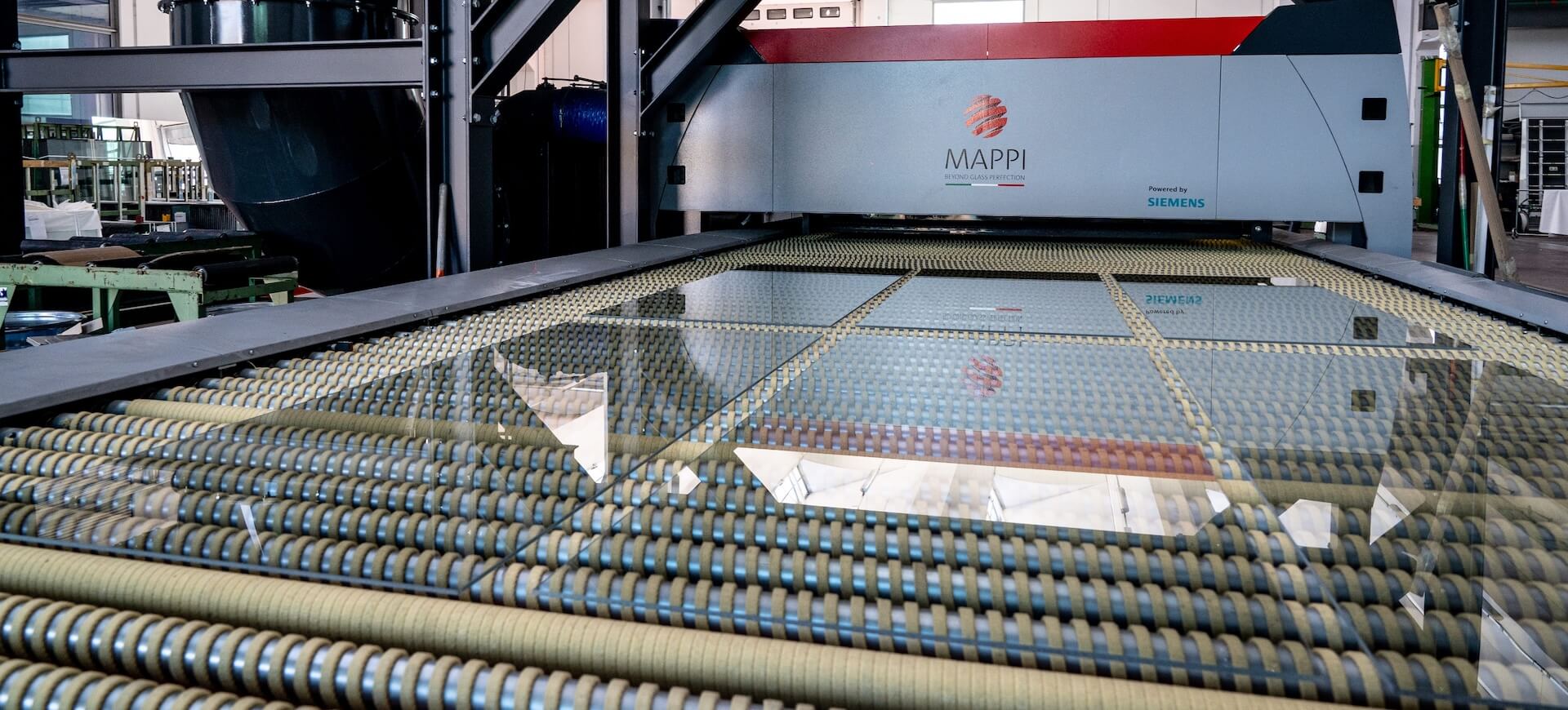

We are the only company in the field with an in-house glassworks, equipped with a tempering oven allows the production process to be completely internalized and controlled: we can rapidly address requests and contingencies while maintaining superior quality control.

Each year, we transform 130,000 sqm of glass into various sizes and shapes, from float glass to laminated and selective glass, and can handle large panels up to 6 metres in size.

Our department is equipped with an automated glass panel cutting and handling machine that ensures rapid and precise handling, even for heavy and bulky loads.

In addition to horizontal and vertical grinding, our processes include thermal tempering and IGU (insulated glass unit) assembly through a fully automated line that also integrates washing and sealing. We are also certified for structural bonding, which is essential for producing naval curtain walls and other glazed structures, adding value to our tailored solutions for complex projects.